Considering a steel or aluminum pop up tent? Look no further! This is our world and we know a ton about this. Real talk: our focus is manufacturing heavy duty aluminum pop up canopy tents, so naturally this is a commonly asked question from our prospects and customers. Now let’s break down the key differences and make the best decision based on your brand and budget.

The easiest way to illustrate the comparison is by focusing on the following areas:

- • Strength & Durability

- • Cost (Initial & Lifetime)

- • Customization & Accessories

- • Warranty

Is a steel or aluminum pop up tent model better for me?

A 10x10 steel frame pop up tent with custom printing typically ranges from $399 - $699, while a 10x10 aluminum frame canopy model with custom printing can range anywhere from $899 to $2,899. So right away we know, steel frame tents are quite a bit cheaper (which is a common problem in this industry) than their aluminum counterparts. But why is there such a big pricing discrepancy?

Comparing Strength & Durability

Design & Materials

Steel is heavier and more dense than aluminum, so if you build a tent with steel, you’re going to add up to 50lbs pretty quickly. For this reason, steel framed tents — especially cheaper ones that you can find at farmers markets — tend to be thinly walled, which means that in comparison to an aluminum tent of comparable weight, the components will be thinner than those found on the aluminum tent.

Aluminum weighs less than steel – it’s roughly 1/3 lighter – which explains why aluminum frames tend to have much thicker walled components. You can build a much thicker frame, while still maintaining a reasonable weight for traveling and solo set-ups. This is one of the key reasons why an aluminum pop up canopy is stronger than a steel model. Aluminum pop up tent legs not only have a larger leg diameter (1” for steel vs. 2” for aluminum) but the thickness (or gauge) of aluminum is twice that of steel.

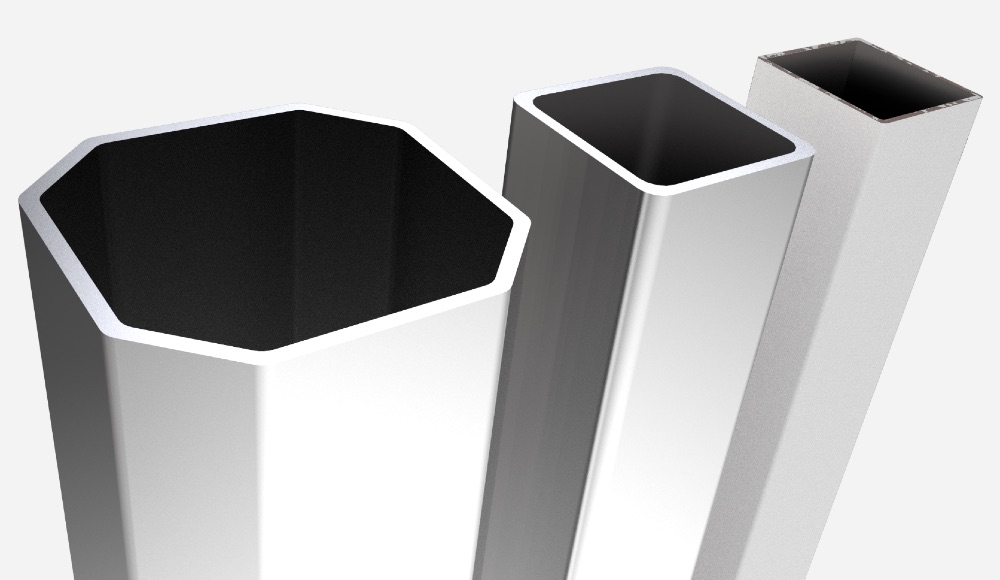

heavy duty (2mm thick) vs medium duty (2mm thick) vs steel leg profile (1mm thick)

We often use the analogy of a pop can vs a soup can. They look similar—and more or less perform the same function—but pretty much anyone can crush a thinly walled pop can with one squeeze. The soup can is thicker and can take a lot more pressure, and if you can crush that, well, I’d like to shake your hand. But also not, because it would probably hurt.

Anodizing vs. Powder-coating

Now let’s talk protective coating, because this is important. It’s basically your tent’s flu shot in October (a little preventative care can go a long way). Quick synopsis: aluminum get anodized and steel gets powder-coated.

Anodizing is an electrochemical process that enhances the surface of a metal. Aluminum has a naturally-occurring oxide layer on its surface and when you anodize aluminum, that oxide layer becomes 100 times as thick, creating an extremely hard, corrosion-resistant layer. Aluminum frames will not rust because the oxide layer is an existing part of the aluminum and cannot be chipped off.

Learn more about anodizing aluminum

Anodized aluminum is second only to diamonds in terms of hardness.

Powder-coating is a process that adheres a secondary protective layer to steel with an electrostatic charge and heat. Since it’s an external layer, powder-coating can be damaged and it is not corrosion-resistant. One of the big drawbacks to steel pop up tent frames is that they are prone to rust, chip and crack.

Connecting Elements

Think of the connecting elements as the joints of a pop up tent. The materials used to make these connections play a big role in determining the overall strength and durability of the pop up tent.

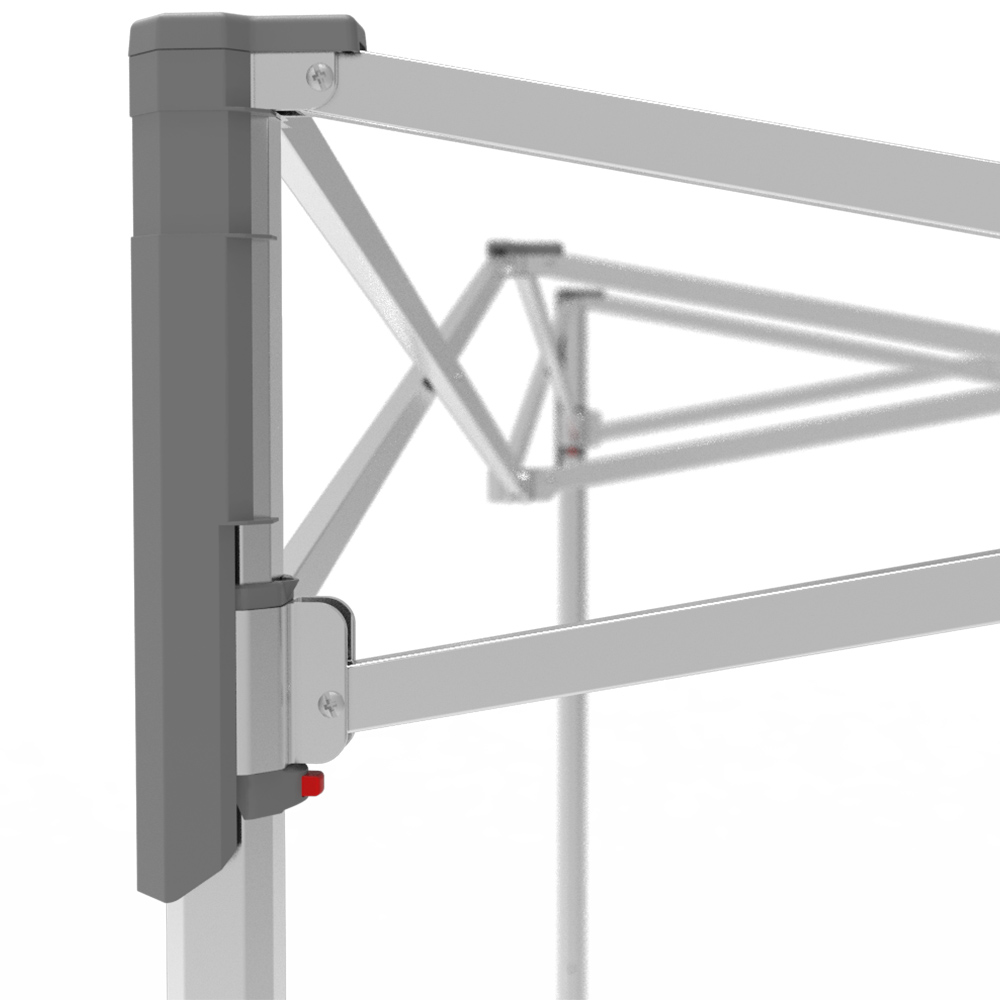

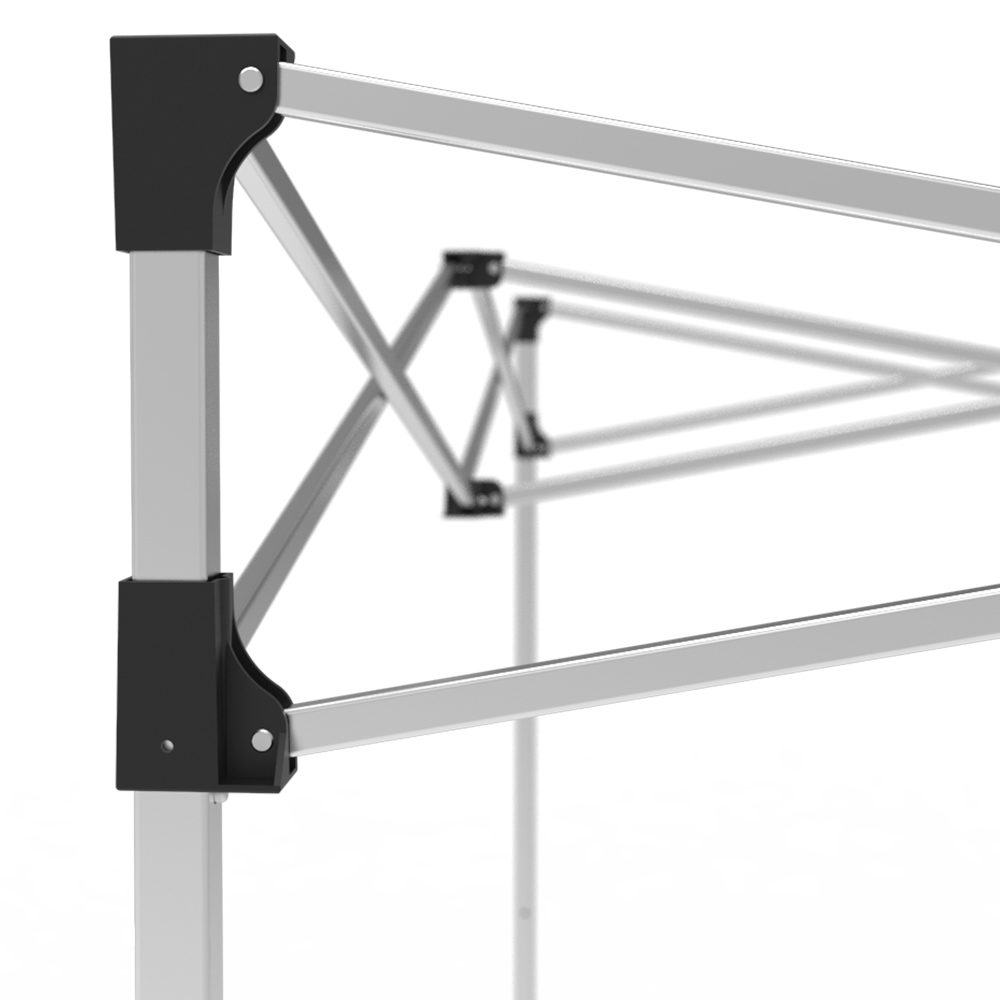

Steel pop up tent models are built to be a low-cost solution, so typically cheaper plastics are used in the connecting joints to help keep costs down. While many aluminum pop up tents also use plastic in the connecting elements—it’s typically a stronger, engineered plastic that is designed to handle greater wear and tear. Aluminum frames that use plastic connectors can be categorized as medium duty frames. The strongest pop up tent models have anodized aluminum frames and anodized aluminum connectors. These frames can be categorized as heavy duty models.

pop up canopy frame with aluminum connecting joints

close up of medium duty pop up tent frame frame

If you’re planning to use your pop up tent model frequently and need it to handle heavier winds and rain, you’ll likely want to invest in a heavy duty aluminum pop up canopy.

Comparing Cost (Initial & Lifetime)

The amount of material and the cost of material used in steel and aluminum pop up tent construction is one of the main cost drivers.

With aluminum weighing ⅓ of steel, more material can be used in the design and construction of the frame, leading to greater strength and durability. At the same time, aluminum costs are often 50-60% higher than steel so higher material costs and 3 times the material means 3-6 times the investment. Again—think about the pop can (steel frame) vs. soup can (aluminum frame) analogy.

Steel pop up tents are built to offer the lowest price point possible while aluminum models are focused more on lasting quality and durability. In the tent industry, it’s really common to make a buying decision based on initial cost, but let’s talk lifetime cost, shall we?

It’s important to ask What level of quality should protect/represent your brand?

Frequency of Use

Beyond cost, frequency of use should play a big role in determining which pop up tent frame type is right for you. Steel pop up tents are best for recreation purposes (the beach, backyard BBQ or family reunion) and can handle 3-4 uses per year in nice weather. Aluminum frames are built for higher frequency use (monthly and even weekly) and can handle wind and rain. We have a handful of customers who use their heavy duty pop up tent model in 35-40 mph winds.

Product Life & Warranties

Because aluminum pop up tent models are stronger and last longer, they carry longer warranties. You’ll find 5-year, 7-year and even lifetime frame warranties for aluminum models.

Replacement Costs

Some brands are comfortable burning through 2-3 steel pop up tent models. It can still be cheaper than investing in a heavier duty aluminum frame. However, there’s still the added cost of downtime while you find a replacement frame or canopy. Consider not only the monetary cost, but also the loss of branded face-time that you may experience if your tent goes out of commission and you need to take a few weeks to redesign, reorder, and wait for your tent to arrive on your front door step. A common phrase we hear from our clients is “responsible purchasing”. And it starts with establishing your expectations.

Summary

The easiest way to summarize the difference between steel and aluminum pop up canopy tents is with a good old fashioned list of pros and cons for each.

Pros & Cons for Steel Pop Up Tent Models

Pros

- • Economical. Steel is a cheaper material. The raw material costs less to acquire, so it’s cheaper to build tents from steel and they cost less to purchase.

- • Very accessible. Go into any big box or sporting goods store and you’ll find a row dedicated to steel pop-up tents.

Cons

- • Steel weighs 3 times as much as aluminum, and so less material is used in the frame design, meaning the strength and durability is far below that of an aluminum model.

- • Steel tent frames are powder-coated which means they’re prone to chipping, scratching and rusting.

- • Since steel pop up tent frames don’t last as long, there’s a higher lifetime cost when you consider the time and money required to replace the frame or canopy every 1-2 years.

Pros & Cons for Aluminum Pop Up Tent Models

Pros

- • Aluminum pop up tent models are comprised of anodized aluminum, which is the second hardest substance next to diamond (satellites, aircraft and military vehicles all use anodized aluminum).

- This is a big reason why aluminum pop up tents last a lot longer.

- • Aluminum pop up tent frames carry longer warranties (5, 7 and even lifetime frame warranties).

- • Aluminum is ⅓ the weight of steel which means more material can be used in the construction of the frame leading to greater strength and durability.

- • You have numerous size options beyond just 10x10.

- • Because aluminum frames last longer, the soft goods (canopy, walls, etc) can be rebranded over time.

- • Aluminum costs are greater than steel, which means they cost more to produce and therefore can be anywhere from 3-6 times as expensive as steel models.